This issues of Perimeter Sealant Joints Around Windows (Head Details) is common.

Matt Gorny, P.E. says the IBC really needs a code limit for spandrel beams that glazing systems are using for support (in both gravity and wind only type connections). These beams need to be stiffer to avoid leaks, breakage etc. It would also help eliminate these unsightly joints.

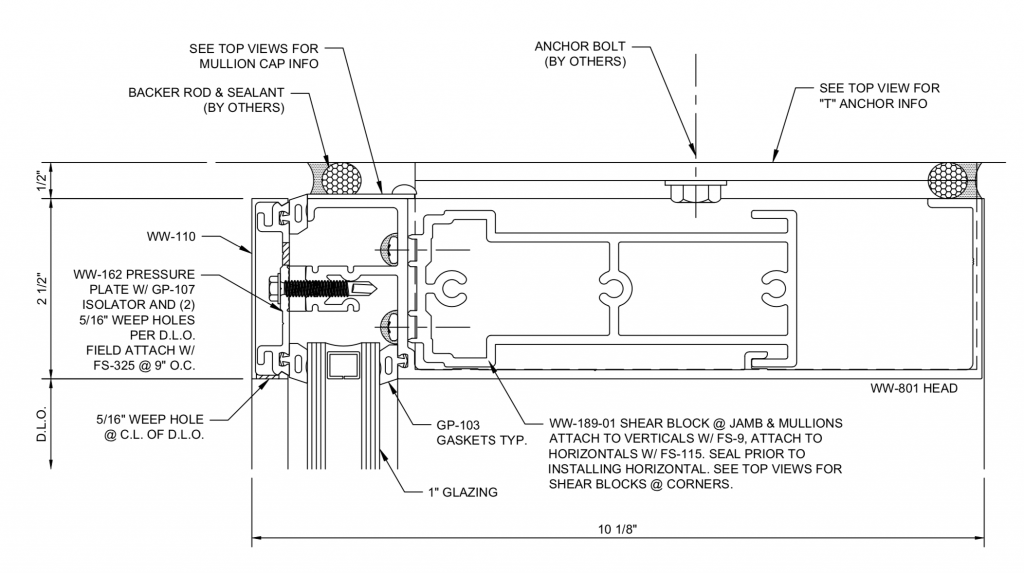

A field note in US Glass elaborates that Architects often question the perimeter sealant joints around our windows, especially at the head detail, where it’s likely any differential movement between the window and adjacent construction occur. The comments usually have to do with, “Why are the joints so wide? Can’t we get them smaller?” And, the response lies at the foot of Mother Nature, the project’s structural engineer and the available sealants, not the window system or detailer.

Metal frames expand and contract when exposed to the conditioned interior air, hot or cold exterior conditions and to direct energy from the sun. On top of that, most specifications require a design of +/- 180 degrees to account for how the metal in the frames will move. While this realistically is more movement than the metal frames will experience, it has a built-in safety factor. And just for the record, aluminum will expand and contract about twice as much as the steel framing used in some fire-rated windows, so the joints can be smaller with steel, to a degree. But we still must account for that specified temperature design range. In a 10-foot piece of metal, aluminum will expand to +/-0.276 inches (7.02 mm), steel +/-0.141 inches (3.56 mm) at 180 degrees.

Next, the amount of live load deflection the structure will experience must be accounted for. If the window or wall is being mounted in an opening where all four sides of it are supported off the same floor, such as in a precast concrete panel opening, there is no relative movement that must be accounted for. But, if the dead load weight of the window is supported on one floor—yet the wind load anchors are connected to adjacent construction supported by the floor above, and the two floors move differently relative to each other due to occupant load changes, such as tenants moving in and out, for example. That movement has to be determined and furnished to the window detailers by the project structural engineer.

So, taking into account that 10-foot length of metal, and adding in a live load deflection of say, 3/8 inches (9.5 mm), there’s a total movement of 0.615 inches (16.53 mm) in an aluminum window and 0.516 inches (13.11 mm) with steel windows. For the size of the sealant joint, those numbers in and of themselves are not that outrageous. Still, we’re only halfway to determining the joint size.

For more information see: