For Glass, Glazing, Metal Panels, Composite Panels, Aluminum or Mixed Materials.

A Cladding design engineer at most companies work with concrete, masonry, and metal stud construction to enclose a building. JEI Structural Engineers are unique; in focus on glass, composite or metal panels.

Specialization in the industry of glazing systems allows JEI cladding engineers to know all the manufactured glazing systems. JEI’s engineers work with these systems daily.

Cladding engineers familiar with other cladding systems may not understand what glass and glazing manufactures provide. There are many pieces and parts to these manufacturers curtain wall and glazing systems that are often missed.

Cladding Design Engineer

Our team is dedicated to cladding design engineering. As a focused cladding design engineering company, the JEI team is up to date on the newest codes and fastest cladding design processes.

In general, cladding is the application of one material over another to provide a skin intended to control the infiltration of weather elements. Recently, architects are using glass more because of its aesthetic properties. Glass also has greater and greater thermal properties. Plus, using glass allows natural light to enter the building, which improve work environments. Not all cladding has to provide a waterproof condition but is instead a control element. This control element may only serve to safely direct water or wind, to control run-off and prevent infiltration into the building structure. Cladding design is also used to prevent noise from entering or escaping. With glass, however, a waterproof environment is required. Cladding applied to windows is often referred to as window capping and is a very specialized field.

JEI relationships with glazing contractors is solid. We value the work of tradesmen.

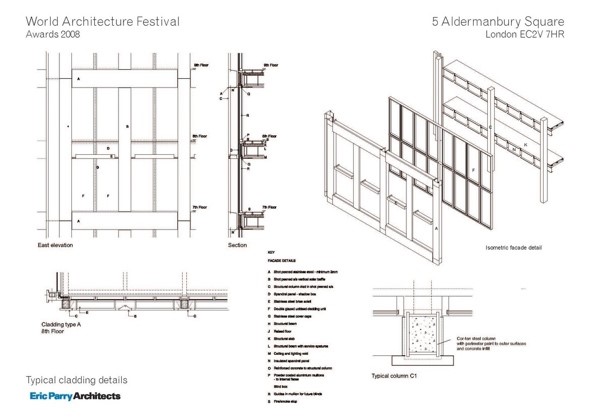

Cladding Detail

JEI works with a network of cladding detail experts and cladding drawing experts. We can provide cladding design and cladding detail work on any commercial building.

Drafting experts that produce cladding detail is rare. Companies do well to build strong relationships of trust with these experts. Geography doesn’t matter anymore. The internet has made working relationships across miles easy.

Glazing contractors require accurate shop drawings to utilize in the field during installation. They need quality cladding detail work to produce these drawings quickly. Glazing contractors are under a lot of pressure from the general contractors, who are in turn under pressure from the building owners to install the glazing system in a timely manner. They need the drawings to show all pertinent details, including engineering, to be approved by the design team before they can begin installation.Quality cladding detail work is very essential to this process.

Cladding Drawings

JEI Structural Engineering works on all types of cladding drawings; providing cladding drawing support through our network. Types of cladding drawings include:

Metal Panel Shop Drawings

Metal panel chop drawings provide an efficient and attractive solution to the building envelope needs of commercial buildings. Over the years, these cladding systems have evolved from the single skin metal cladding often associated with agricultural buildings, to highly developed systems found in hospitals, courthouses, high schools and all other commercial building types. However, as with all construction components, the ability of the building envelope to satisfy its functional requirements is dependent on its correct specification and installation. Equally as important, is its interaction with the other elements of the building envelope and structure.

Communication between the architect, engineer of record, glazing contractor and cladding engineer is critical.

At JEI, we’ve found that submitting, Request for Information (RFI), early in the design process saves time and money for glazing contractors. This is a critical element of low cost, fast engineering, since current codes and manufacturer capabilities often do not line up with architectural requirements or current regulations.

Metal Panel Design

Metal panel design is a specialty. Products are produced by metals fabricators who focus on providing innovative engineered systems. There are new unique and sustainable claddings to select from. Such as; Aluminum Composite Panels, Plate, Colored Stainless, Copper, Zinc, Phenolic Material, Fiber Cement and others.

The metal panel design industry is continuously incorporating new methodology into systems to add innovative features and installation improvements in the field. These systems add aesthetics to buildings, as well as thermal performance. Metal panel design is environmentally responsible, utilizing green building elements in most new projects.

JEI Structural Engineering is guided by our cultural values of servant leadership, integrity, innovation and quality working with metal panel design. We are committed to our customer’s success through safe product analysis, adaptable services to enhance value, and innovative design concepts that comply with the most up to date codes and regulations.

Metal Panel Detail

JEI Structural Engineering works with a variety of multi-service drafting firms, offering metal panel detail. We work with glazing shop drawing strategic alliances for metal wall and roof panel systems, rain screen systems and architectural drafting utilizing Autodesk AutoCAD 2014, Revit 2014 and more current and custom software programs.

Our partners have architectural drafting and documenting experience that spans 30 years.

Services include:

- Commercial architectural contract drawings.

- Aluminum composite material (ACM) wall panel shop drawings.

- Single skin metal wall and roof panel shop drawings.

- Insulated metal wall and roof panel shop drawings.

- Insulated composite backup panel shop drawings.

- Phenolic and fiber cement rain screen wall panel shop drawings.

- Custom architectural sheet metal.

Metal Panel Design

Metal panel design is growing. A wide variety of panelized metal wall systems are available for installation as a building’s exterior wall cladding. Each system must be specially adapted to its intended building use. Metal wall panels are usually fabricated of aluminum but can also be manufactured from steel, stainless steel, copper, or composite materials.

Metal panel design engineering often involves proprietary designs in which a manufacturer adapts his system to the architect’s design. As part of the engineering design process, the architect will select a type of metal panel system and provide architectural details that depict the relationship of the metal panel system to the adjacent building systems.

Generally,

Architects do not provide comprehensive detailing for the metal panel system as part of the construction documents so glazing contractors work with JEI Structural Engineering to complete the drawings. The project specifications, shop drawings, and submittal review are critical to the success of the project. JEI Structural engineers work closely with glazing contractors to ensure the system is designed and installed per code requirements.

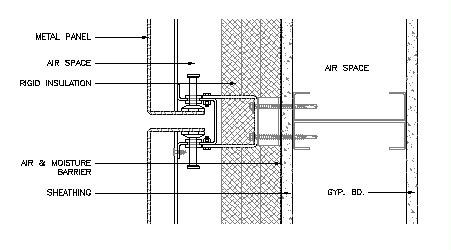

When the metal panel system is selected, engineers decide if the system requires an air and water barrier or rain screen. The air and water barrier requirements need to be clearly shown on the contract documents since the metal panel manufacturer does not provide these systems or their detailing.

In the specification, the engineering designer must select the types of metal panels that will meet design criteria and establish the panel performance criteria. Performance criteria need to include:

- Wind loading

- Seismic design criteria

- Deflection criteria

- Air infiltration criteria

- Water test performance criteria

- Panel flatness criteria

- Panel tolerance criteria

- Thermal movement criteria

- Performance testing criteria

- Fire resistance ratings, if required

- Sound transmission criteria

- Insulation criteria

- Performance criteria for air and moisture barrier or rain screen

After the Project has Gone Out for Bid

The contractor selects a metal panel system based on the specification. The shop drawing review process is critical to the success of a project. During this process, the manufacturer adapts the system to the specific building. The shop drawings are accompanied by structural calculations that need to be performed by a structural engineer licensed in the project state; (this is especially important for states in high seismic zones). Finding an engineer with expertise is critical to the process.

The codes are comprehensive and changing. Glass and glazing engineering is not taught it structural engineering universities. Experience counts in selecting a structural engineer in glass and glazing. A JEI Structural engineer is assigned to the project and often will send out RFI’s to the architect and engineer of record to answer important questions that save the glazing contractor time and money.

During the shop drawing review process, the manufacturer, installer, general contractor, and architect need to review the interface of the metal panels to adjacent systems such as windows and other cladding systems. If the building features a secondary air and moisture barrier or rain screen, the structural attachment of the metal panels needs to be reviewed to verify that it does not compromise the secondary barrier. During the shop drawing review process, construction tolerances for joint sizes need to be reviewed and accepted by the manufacturer, installer, general contractor and architect.

Aluminum Composite Panel Design

JEI Structural Engineering is the leader in the design of composite panel design and composite metal wall panel systems. Working toward servicing customers in all 50 states and abroad, JEI engineers design composite metal panel systems for commercial, institutional, governmental, manufacturing projects.

Composite Panel Detail

JEI Structural Engineers work with experts in composite panel detail drafting. JEI has a network with specialty in CAD Drafting & Design for the Commercial Building Envelope Industry specializing in metalwork. Our partners work with Aluminum Composite Material (such as Reynobond®, Alucobond®, etc.), all types of Ribbed Metal siding (such as Fabral®, Centria®, etc.) , and Phenolic Wall Panels (such as Trespa® or equal).

The JEI Structural Engineering team provides services through the entire project process, from the Submittal Drawings to revisions to Fabrication Drawings JEI Structural Engineers and composite panel detail drafters are up on software changes in the industry. JEI Structural Engineer drafting partners use AutoCAD, Revit Architecture, Inventor, and Rhino 3D. They provide a 3D software package that is specifically for the Curtainwall and Wall Cladding Systems Industry which integrates into AutoCAD. Other software is available upon request. Working close with you to provide the services to your exact needs.

Composite Panel Design

Composite panel design can feature two sheets of metal adhered to a core material. These composite panels are usually stronger than lap-seam panels and provide built-in insulation to the wall system. The thickness of the metal sheet is generally less than 0.05 inches (1.10 mm.) The overall panel thickness varies, depending on the insulation, from 1.2 inch to over 2 inches. Composite metal wall panels are often ship-lapped with adjacent panels like lap-seam panels. Types of composite panels include:

Foamed-Insulation Core Metal Wall Panels:

These panels have metal facings with insulation foamed into place during fabrication.

Laminated-Insulation Core Metal Wall Panels: These panels have the metal facings laminated to preformed insulation boards. Panels can have tongue-in-grove joints for interface with adjacent panels or framed edges where perimeter extrusions attach the panels.

Honeycomb Core Metal Wall Panels: These panels have metal facings bonded to a honeycomb core.

Aluminum Panel Design

Aluminum panel design and Aluminum composite cladding system or ACP is typically a metal curtain wall system. ACP is made from lightweight aluminum with hard insulation. Aluminum composite cladding is used for exterior cladding, column covers, fascias and canopies, interior wall and partition panels, parapets, louvers and sunshades.

Every JEI Structural engineer has extensive experience and skill in providing ACP engineering design. JEI outsources drawings to one of our strategic alliances in an extensive network of glazing industry drafters. Our alliances in ACP detailing also include 2D & 3D detailing & drafting. JEI Structural Engineering has a highly successful track record and also a growing repetitive clientele. JEI Structural engineers meet the client’s demands and expectations with focus on quality and reliability.

Aluminum Panel Detail

JEI Structural Engineers work on aluminum panel detail projects large and small. Our Architectural Panel Engineers have experience with panels and will save glazing contractors, architects and manufacturers time and money. JEI experience produces high quality engineer calculation packages that are fast, friendly and affordable. Engineering services by JEI Structural Engineering are for all types of wall and roof panel projects including but not limited to aluminum, composite, honeycomb, insulated, corrugated, steel, cement, and copper. Also, JEI offers engineering services for column covers, mesh panels, copings, NOA Submittals, and also Panel Chart Design.

- Aluminum Panels

- Composite Panels

- Honeycomb Panels

- Currogated Panels

- Insulated Panels

- Cementious Panels

- Column Covers

- Mesh Panels

- Copings

- NOA Submittals

- Panel Chart Design

Aluminum Consulting Engineer

The combined professional experience of JEI Structural Engineering aluminum consulting engineer and affiliates represents deep technical knowledge covering all aspects of aluminum engineering design related to the glass and glazing industry. This knowledge was acquired through decades of experience coupled with hundreds of real world projects across the world.

Our experienced staff of engineers has completed designs for all types of specialty glass, glazing and metal panel facades. JEI Structural Engineering specialize in aluminum structures and glass and also glazing systems of all types. JEI has projects across the United States. Let our experience in the industry put the best engineering practices to work for you.

Aluminum Detail Engineering

Aluminum detail engineering is the future. In the late 1800s, aluminum was the most expensive metal in the world. A few decades later, it was being used to build everything. Aluminum has been around for thousands of years, but until recently, it was very expensive and a poor building material. The discovery of cheaper manufacturing processes and strong aluminum alloys that were lighter than steel completely changed entire industries in the early 20th century.

Consider architectural renderings of tomorrow’s city. Buildings are made of glass exterior.

Other Glass & Glazing Engineering Services

JEI works with limitless design possibilities for commercial skylight projects. We work with a Curtain Wall Company manufacture, glazing contractor or architect to provide Commercial Curtain Wall Details and Curtain Wall Design or Curtain Wall Consulting.

Our focus is exclusively glass & glazing industry expertise including work as a:

Get a FREE Quote

Email Construction Docs for FREE Estimate. Whatever your needs, JEI Structural Engineers are trained to add value to any project.